Comparing Label Materials: BOPP vs. Vinyl for Your Product Packaging

So you’re on the hunt for the perfect label material for your product’s packaging. You’ve probably seen Biaxially Oriented Polypropylene (BOPP) and vinyl as popular contenders. These two materials are some of the most commonly used facestocks (the material that holds ink on one side and adhesive on the other) for a good reason, but which one is right for you?

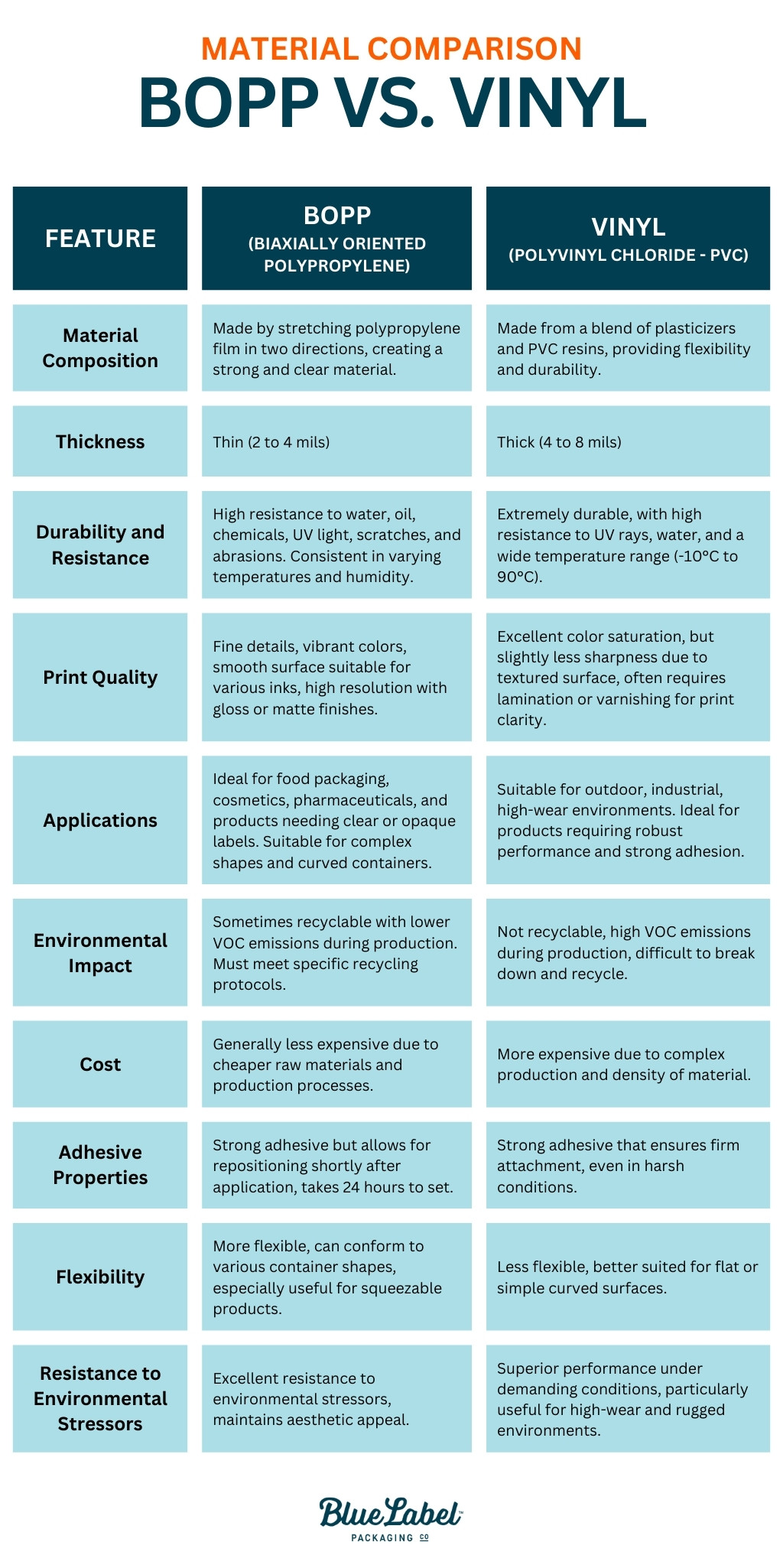

You might be wondering about their durability — who doesn’t want a label that lasts? And what about waterproof capabilities? No one wants a soggy label. Does the print quality make a difference between the two? And let’s not forget the cost. Balancing quality and affordability can help you protect your bottom line while ensuring your labels are up to standard.

Let’s look at the key considerations that typically arise in the decision-making process about label materials. Use this guide to make an informed choice that aligns with your brand and operational demands.

Material Properties and Composition

BOPP: Biaxially Oriented Polypropylene

BOPP, or Biaxially Oriented Polypropylene, is a special type of material created by stretching polypropylene film in two directions. This process makes it incredibly strong and clear. Think of it like pulling plastic wrap both ways until it’s tough to tear. This process results in a durable, lightweight material with excellent moisture barrier properties.

Vinyl: Polyvinyl Chloride (PVC)

Vinyl labels are crafted from polyvinyl chloride (PVC), a robust and versatile material. The process starts by forming the vinyl using a blend of plasticizers and PVC resins, which are heated and rolled to achieve the right thickness and smoothness. The plasticizers provide flexibility, and stabilizers enhance durability.

A protective coating may increase resistance to scratches and environmental factors. Vinyl labels are also known for their strong adhesive backing, which ensures they stay firmly attached to surfaces regardless of exposure to various elements.

Durability and Resistance

BOPP: Thin and Flexible

BOPP labels are thinner than vinyl labels, at around 2 to 4 mils thick, but don’t let their slim profile fool you — they’re built tough! These labels can handle changing environments without fading, degrading, or peeling. Whether they’re exposed to water, oil, chemicals, or even harsh UV light, the printed graphics and text stay crisp and clear.

BOPP labels are also exceptional at resisting scratches and abrasions. They perform consistently well in storage environments where temperatures and humidity levels can vary, making them a reliable choice for keeping important information visible and intact.

Vinyl: Thick and Rigid

Vinyl labels are impressively robust, clocking in at a standard thickness between 4 to 8 mils. They are specifically crafted to hold up in outdoor and high-wear settings, making them a fantastic choice for a durable label material.

Vinyl labels are known for their ability to stay put even when the temperature shifts dramatically. Withstanding temperatures ranging from a chilly -10°C to a scorching 90°C, these labels ensure your important markings remain firmly in place no matter their conditions. Looking for a highly moisture-resistant label? They also have excellent resistance to UV rays and water.

Print Quality

BOPP: Fine Details

BOPP labels can achieve more vibrant and precise color reproductions than other material types thanks to their smooth surface that prints beautifully with a variety of inks, including aqueous, UV-cured, and even thermal transfer inks. BOPP stands out for its ability to provide fine detail and a broad color gamut with gloss or matte finishes, each giving a unique aesthetic.

Vinyl: Excellent Color Saturation

Both vinyl and BOPP can have similar print quality. Vinyl’s slightly textured surface can sometimes result in less sharpness and precision in printed graphics and text. This texture also means that white vinyl labels can handle a variety of inks, including more eco-friendly options, to achieve vibrant color reproduction.

Vinyl labels often require specific finishing techniques, such as lamination or varnishing, to boost their durability and maintain print clarity. Though robust and versatile, vinyl labels may not deliver the ultra-fine detail BOPP labels can provide. Consequently, while vinyl is an excellent choice for many applications, it might not match the aesthetic refinement offered by BOPP materials, particularly for designs demanding high resolution.

Applications

BOPP: Food Packaging, Cosmetics, Pharmaceuticals; Clear and Opaque Applications

When it comes to BOPP label applications, it’s easy to see why they are the go-to choice for achieving an “invisible” look with high gloss and impressive transparency. BOPP’s flexibility allows it to conform to a wider range of container shapes, making it perfect for small or curved packages where vinyl might struggle. This adaptability is particularly crucial for complex-shaped containers or squeezable products, where a non-rigid, clear BOPP label can create the illusion that the graphics are printed directly on the container.

BOPP labels can be shifted if needed shortly after applying and usually take 24 hours to set completely.

Their resistance to such stressors ensures that the labels remain intact and maintain their aesthetic appeal, providing both functional and visual benefits. This makes BOPP labels suitable for products in the food, beverage, and industrial sectors, where exposure to environmental stressors is common.

Vinyl: Outdoor, Industrial, High Wear Environments

Vinyl labels’ exceptional durability means you can use them indoors and outdoors, making them ideal for a multitude of applications requiring robust performance in either or both settings.

Their tough nature and strong adhesive properties make them particularly useful for labeling high-wear, high-moisture, and high-UV-exposure consumer or industrial products. Thanks to their superior performance under demanding conditions and stronger adhesive backing, vinyl labels are often preferred over BOPP labels for products that experience more rugged environments. This thickness of vinyl labels also makes them popular die-cut stickers.

Environmental Impact

BOPP: Sometimes Recyclable, Low VOCs

Unlike paper or cellulose-based labels, BOPP materials are not biodegradable. Yes, some BOPP labels are recyclable. They must meet the Association of Plastic Recyclers (APR) Critical Guidance Protocol for high-density polyethylene (HDPE) recycling, which can be processed alongside other plastic materials at recycling facilities. In the past, the label needed to be separated from the container; this certification verifies that labels that remain won’t affect the recycling process.

Compared to vinyl labels, BOPP labels often have a lower environmental impact during production. The vinyl manufacturing process and adhesives typically release higher levels of volatile organic compounds (VOCs), which can contribute to air pollution.

Vinyl: Not Recyclable, High VOCs

The production and adhesives of vinyl labels release volatile organic compounds (VOCs), which can contribute to air pollution. This is a significant disadvantage compared to BOPP labels, which generally have a lower VOC emission profile.

Vinyl labels also face challenges when it comes to end-of-life disposal. Built tough and often layered with finishes that cannot be separated, they typically have a more difficult time breaking down and cannot be recycled in regular waste streams. The recycling process for vinyl is complex and not widely available, making it challenging to mitigate its environmental footprint through recycling alone.

Cost

BOPP: Less Expensive

Generally, BOPP labels tend to be more cost-effective than vinyl labels. This cost efficiency stems from several factors, including the raw materials used, the thickness of the material, and the manufacturing process. BOPP labels are produced using polypropylene, which is typically cheaper and more abundant than the PVC used in vinyl labels.

Vinyl: More Expensive

Conversely, vinyl labels, with their more complex production and density of material, typically incur a higher cost than BOPP. This cost discrepancy makes BOPP labels an attractive option for businesses looking to balance performance with budget considerations.

Let Blue Label Packaging Help You Decide

We know you don’t get a second first impression. A high-quality label on the outside is as important as the product on the inside. Let Blue Label Packaging help your product succeed with customized label solutions. Contact us today!