Common Labeling Mistakes to Avoid: Application Issues

Application issues come in many forms and lead to a range of problems. Misapplication could lead to tearing, wrinkling, flagging, or peeling. Other factors can wreak havoc with the actual application process itself. No matter the problem, you can take measures to prevent each problem ahead of time. Here are some notable reasons why you’d encounter label application issues.

Your Label isn’t Right for Your Container Surface

What you apply your labels to can play as much of a role in label issues than the application process itself. Each surface has its own challenges, which can call for a different adhesive or label material. For example, a glass wine bottle has a different surface energy and adhesive needs than a polyethylene pouch for candy. This means that you need to identify potential surface issues to ensure that your labels stay on your products during – and long after – the application process.

The Applicating Environment Poses Problems

Even if you have the right label material and adhesive for your container, they may not be a good fit for your applicating environment. There are a variety of factors that impact label application. Certain adhesives won’t work nearly as well at different temperatures, which can be a major issue if application is performed in a hot or cold environment. As a result, you’ll want to take these conditions into consideration when selecting the right label adhesive.

There’s also potential for contaminants like dirt, dust, and moisture to prevent proper adhesion. The product itself can even pose a problem for the application environment. Spilled oil or soap won’t make it any easier for an adhesive to take hold. No matter the potential problem, it’s important to try and keep your containers and environment as clean as possible for application.

The Unwind Direction is Wrong

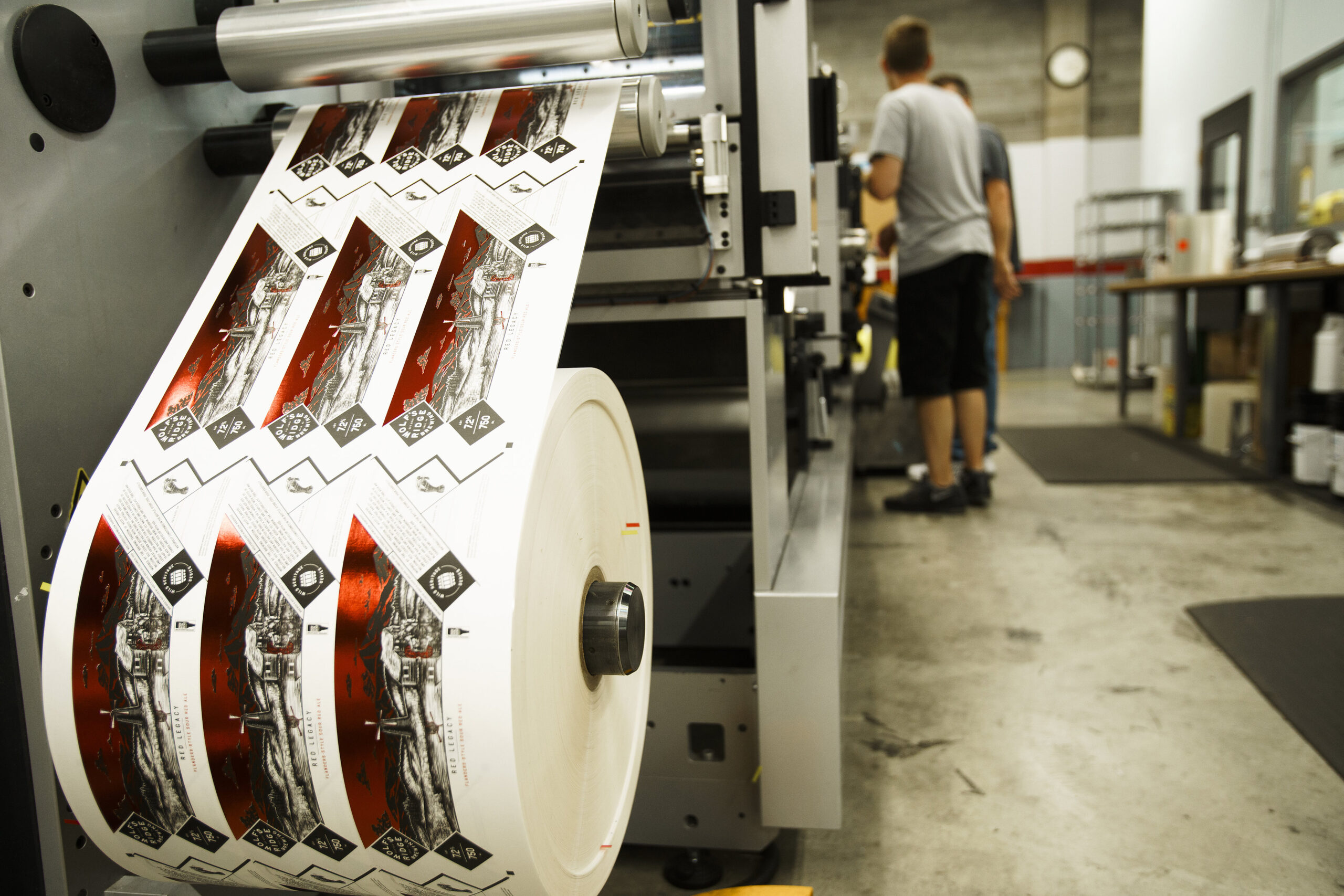

Even if you have the right label adhesive and your applicating environment is clean, you can still have major issues if your rolls aren’t oriented correctly. Since your labels are printed on rolls, it’s crucial that you consider both how those labels are printed on the substrate and how they’ll be applied to your container. If you don’t, you’ll likely end up with an incorrect unwind direction that results in improper label placement.

Simply put, the unwind direction is the orientation of your labels as they come off a roll. Depending on your container or application equipment, you will need a specific unwind direction. For example, one machine may dispense labels on the left side first or require your design to be turned 90 degrees for proper placement. It’s key that you take the application process into account and visualize how your labels are applied to your product. That way you can communicate the correct unwind direction to your printer so that you avoid issues before they happen.

Your Label Rolls Aren’t Right for Your Equipment

Unsurprisingly, your applicating equipment could be the source of application issues. Certain machines only handle certain roll sizes. That means equipment designed to use 8-inch rolls won’t accommodate larger sizes. As a result, improper roll sizes can cause your application process to come to a complete stop.

Incorrect roll sizes are fixable, but it still requires your printer to resize and rewind them. In turn that costs you more time and money for an entirely preventable problem. Whether you use your own equipment or work with a co-packer, make sure you know what size rolls your equipment can handle. This size issue is typically referred to as “maximum outer diameter” or “max OD,” That way you can communicate these sizes to your printer and be proactive in preventing issues.

Work with the Right Label Printing Company

No matter the application issue you want to avoid, a good printer can help you find potential solutions to your label problems. That’s why Blue Label develops a collaborative relationship to work with our customers so that we understand their needs and identify ways to avoid issues ahead of time.

Ready to talk about your next custom product label project? Contact Blue Label today to get in touch with one of our experts.