How to Translate Your Brand Identity into Packaging and Labels: A Step-by-Step Guide

While you might not judge a person based on one meeting, products often don’t get a second chance on a crowded shelf. Let’s face it — when it comes to shopping, customers all judge a book by its cover, or in this case, a product by its packaging. Studies say about 70% of consumers make snap decisions based on packaging alone — tough for your amazing product on the inside!

Let’s dive into the consumer psyche and how your packaging choices can help you connect to your ideal audience.

The Significance of Brand Identity in Packaging and Labeling

It’s not only your choice of color palette and the feel of a quality product label design that matters. Nearly two-thirds of shoppers feel more connected with brands that share their values, often thanks to clever packaging that tells a story. If a product’s packaging catches the consumer’s eye in the first few seconds, we are a whopping 81% more likely to toss it into our cart.

What is this magic that compels consumers to pick one product over another? One ingredient is a well-communicated brand identity.

What Is Brand Identity?

Author and branding guru Seth Godin once said, “A brand is the set of expectations, memories, stories and relationships that, taken together, account for a consumer’s decision to choose one product or service over another.”

Brand identity encompasses the visible elements of a brand, including its:

- Name

- Logo

- Color palette

- Typography

- Imagery

- Tone of voice

Together, they create a unique image in the consumer’s mind. These components work in harmony to convey the brand’s message and values.

Where Packaging and Labeling Meet Brand Identity

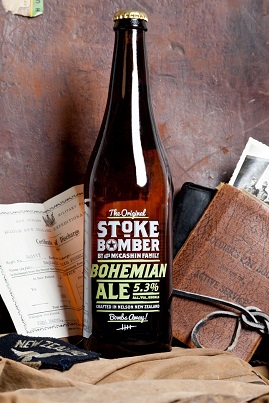

Packaging and labeling play a crucial role as the physical embodiment of a brand’s identity. They are often the first touchpoint a consumer has with a product, making them essential in creating lasting impressions.

Well-designed packaging not only attracts attention on the shelf but also communicates the brand’s essence, values, and intentions. Effective packaging can enhance a consumer’s experience, reflecting quality and care in the product within.

Once you’ve started growing a loyal fanbase, consistent design elements, packaging, and labels can reinforce brand recognition, fostering customer trust and loyalty.

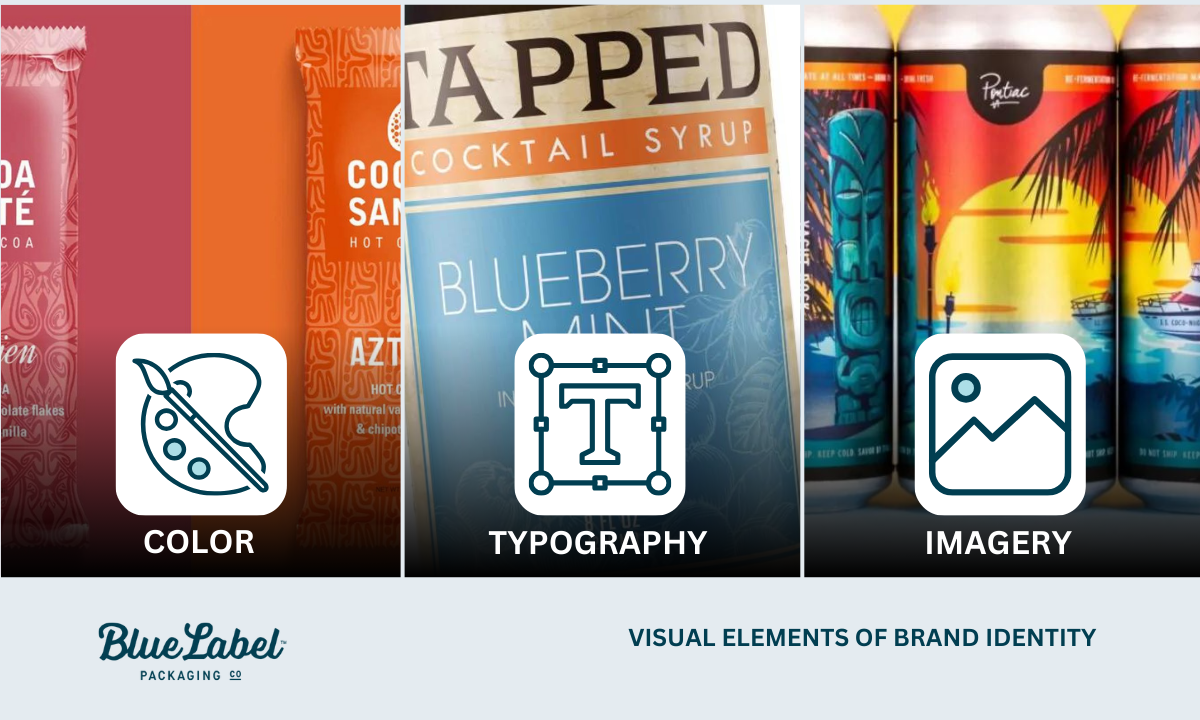

Key Visual Elements of Brand Identity

When translating brand identity into packaging, several key visual elements must be considered:

- Color: The choice of colors in packaging influences consumer perception and can evoke specific emotions. For example, blue often conveys trust and reliability, while green is associated with eco-friendliness and health.

- Typography: The fonts selected for packaging should align with the brand’s personality and tone. Elegant script fonts might suggest luxury, while bold, sans-serif fonts can impart a modern, approachable feel.

- Imagery: The visuals used, whether photographs, illustrations, or graphics, should resonate with the brand’s message and audience. They can enhance storytelling, making the product more relatable and memorable.

The Impact of Branding and Design on Profitability and Marketability

Branding and design are two of the biggest parts of your brand equity. They shape consumer perceptions and can significantly influence purchasing decisions. Here’s how they impact your bottom line:

- Generates Organic Word of Mouth (WOM) Marketing: A strong brand identity attracts new customers and helps retain existing customers, leading to repeat purchases and valuable word-of-mouth promotion.

- Accelerates Growth Through Recognition: Unique packaging and label design make your product memorable and easy to find—that’s what we call brand recognition.

- Adds Perceived Value: Eye-catching design helps your product stand out, helping you justify your price point.

- Simplifies Marketing Efforts: A clear and consistent brand across products and platforms makes sales and marketing easier.

Shopper Psychology: How Packaging Influences Consumer Perception

Packaging is far more than just a protective layer for products; it is the first touchpoint between consumers and your brand — and it turns out that most of the time, the average shopper doesn’t know they’re being judgemental.

Harvard Business School professor Gerald Zaltman highlights in his book How Customers Think: Essential Insights into the Mind of the Market that as much as 95% of the decisions customers make when purchasing occur within our subconscious mind.

The design, color, shape, and material of packaging can significantly affect consumer perceptions and buying decisions. Eye-catching packaging can evoke emotions and attract attention, driving impulse purchases and establishing a brand’s identity in a crowded marketplace. Packaging can signal quality and sustainability, influencing consumers’ choices in an increasingly eco-conscious market.

Designing for Your Target Market

A deep understanding of their preferences, values, and lifestyles is essential to ensure that packaging resonates with your target audience. Here are some tips for creating effective packaging:

- Research Demographics: Conduct market research to understand your audience’s characteristics, including age, gender, and interests.

- Visual Elements: Use colors and graphics that appeal to your demographic. Younger consumers might prefer bold, playful designs, while older consumers may appreciate classic and understated elegance.

- Functional Design: Consider the practical needs of your target market, such as ease of use, convenience, and portability, ensuring that your packaging meets their expectations.

How Types of Packaging Speak to Different Demographics

Packaging should speak to your brand’s key personas.

- Eco-Friendly Packaging: Brands like Method and Haagen-Dazs have successfully adopted sustainable packaging that appeals to environmentally conscious consumers, reinforcing their commitment to sustainability.

- Luxury Packaging: Companies like Chanel use elegant, minimalist designs to convey a sense of exclusivity and high quality, resonating with affluent clients seeking premium products.

- Whimsical Packaging: Brands targeting families and children, like M&M’s, often employ vibrant colors and playful illustrations, making their products visually appealing to younger audiences and their parents alike.

How to Communicate Brand Identity Effectively to a Designer

Before you talk to the designer, you’ll need to get your ducks in a row. This means creating a clear common language to communicate with each other.

- Define Your Brand’s Vision and Values: Outlining the core principles that drive your brand. What is its mission and vision? Articulate the values you want the brand to embody and the problem you want to solve with your product.

- Identify Your Target Audience: purchasing behaviors. This information helps the designer understand whom they are designing for.

- Choose a Tone and Voice: Describe the tone of communication that your brand will use — will it be playful, serious, modern, or nostalgic? This will guide the designer in selecting colors, typography, and styles that align with your brand personality.

- Create a Brand Guide or Identity Brief: Your brand will include all the above plus examples of your buyer persona, logo use, brand colors, and fonts. (Pro tip: look at other industry-adjacent brand language and style guides to get a feel for what to include and then customize it to your brand’s voice and audience.)

What to Give to a Designer

It’s helpful to include a few extras along with the brand guide. Most experienced designers can seamlessly switch between brand aesthetics, but they tend to work better with visual references than only verbal ones.

- Provide Visual Inspiration: Include mood boards, examples of competitor brands, or any visuals that resonate with your brand’s identity. This will help the designer visualize your expectations.

- Outline Specific Requirements: Specify any essential elements or constraints in the design, such as logo usage, color palettes, and typography guidelines. Be clear about what must and must not be included.

Collaboration Strategies

These are some tips to keep the design process smooth. Really solid communication will save you time and money.

- Be Clear and Concise: Use straightforward language and avoid jargon when discussing your brand identity. Ensure that all key points are easy to understand and direct.

- Encourage Questions: Foster an open atmosphere by inviting the designer to ask questions for clarity. This helps prevent misunderstandings and aligns expectations.

- Provide Context: Explain why certain elements are important to your brand. Sharing the reasoning behind your choices gives the designer a deeper understanding of your vision.

- Regular Check-Ins: Schedule periodic meetings to discuss progress and address any concerns. This keeps everyone on the same page and allows for adjustments based on client feedback.

- Constructive Feedback: Offer feedback that is specific and actionable. Instead of saying you don’t like a design, explain what aspects do not align with your vision and why.

- Celebrate Milestones: Acknowledge completed phases in the design process to maintain motivation. Recognizing efforts helps build a positive working relationship and encourages designers to deliver their best work.

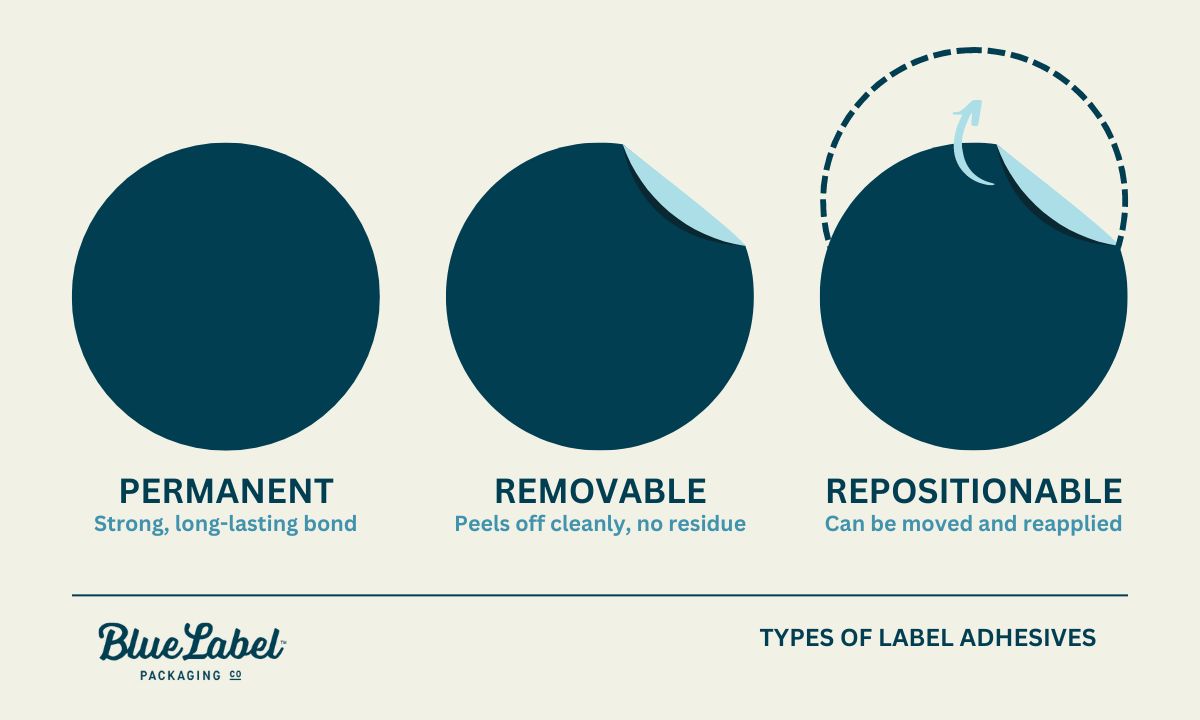

Choosing the Right Materials and Styles Based on Your Brand Identity

Material Selection

When selecting materials for your packaging, it’s crucial to consider how each option can align with and enhance your brand identity.

For instance, paper offers a classic, eco-friendly choice that can be tailored with various textures and finishes for a unique touch.

BOPP (Biaxially Oriented Polypropylene) is a versatile and durable material that works well for products requiring moisture protection while maintaining a clear design aesthetic.

Vinyl, known for its vibrant colors and flexibility, can convey a modern and durable impression, making it suitable for brands looking to stand out in a competitive market.

Style Considerations

Your packaging style should ultimately serve to reflect and elevate your brand’s identity and values.

A minimalist approach, like the one famously used by Apple, can communicate sophistication and modernity, appealing to consumers who value simplicity and elegance.

On the other hand, luxury packaging often employs high-quality materials and intricate designs to create an impression of exclusivity and prestige. The perfume industry does an excellent job using custom packaging and high-end label finishes to speak to a high-end buyer.

Eco-friendly packaging can resonate with environmentally conscious consumers, showcasing a commitment to sustainability. Lush is a great example, showcasing bold, eco-friendly packaging that aligns with their ethical stance.

The Importance of Brand Consistency Across Products and Product Lines

Keeping your brand consistent across all products and packaging is key to building consumer trust. When customers see a uniform brand experience, it boosts their recognition and makes them feel more connected to your products. This connection can lead to increased loyalty, as people tend to stick with brands they know well.

To achieve this, brands should create clear brand guidelines for visual elements like logos, colors, and typography and ensure that teams are trained on these standards.

Should you live and die by your brand guide? Not always. When launching new products or entering different markets, it’s vital to adjust your branding thoughtfully, maintaining your core identity while appealing to local tastes. By focusing on consistency, companies can grow while solidifying their presence in the market.

Blue Label Can Help Connect Your Brand to Your Packaging

Next time you’re designing labeling or packaging, remember that a little thought toward branding, materials, and intent can go a long way toward turning heads and creating a loyal customer base.

Contact us today for a quote for custom labels or just go get answers to any of your labeling or packaging questions.