Professional vs. DIY Label Applicators: Which is Best for Your Business?

There are a multitude of options for label application. Some businesses opt to handle application themselves through means that range from sophisticated machinery to the most manual tools of all – your hands. Other business turn to professional applicators, such as a mobile canner.

Simply put, it’s essential to identify the best applicator for your business. However, the most effective option depends on your exact needs. Let’s break down the different types of applicators that are available and which route makes the most sense for your needs.

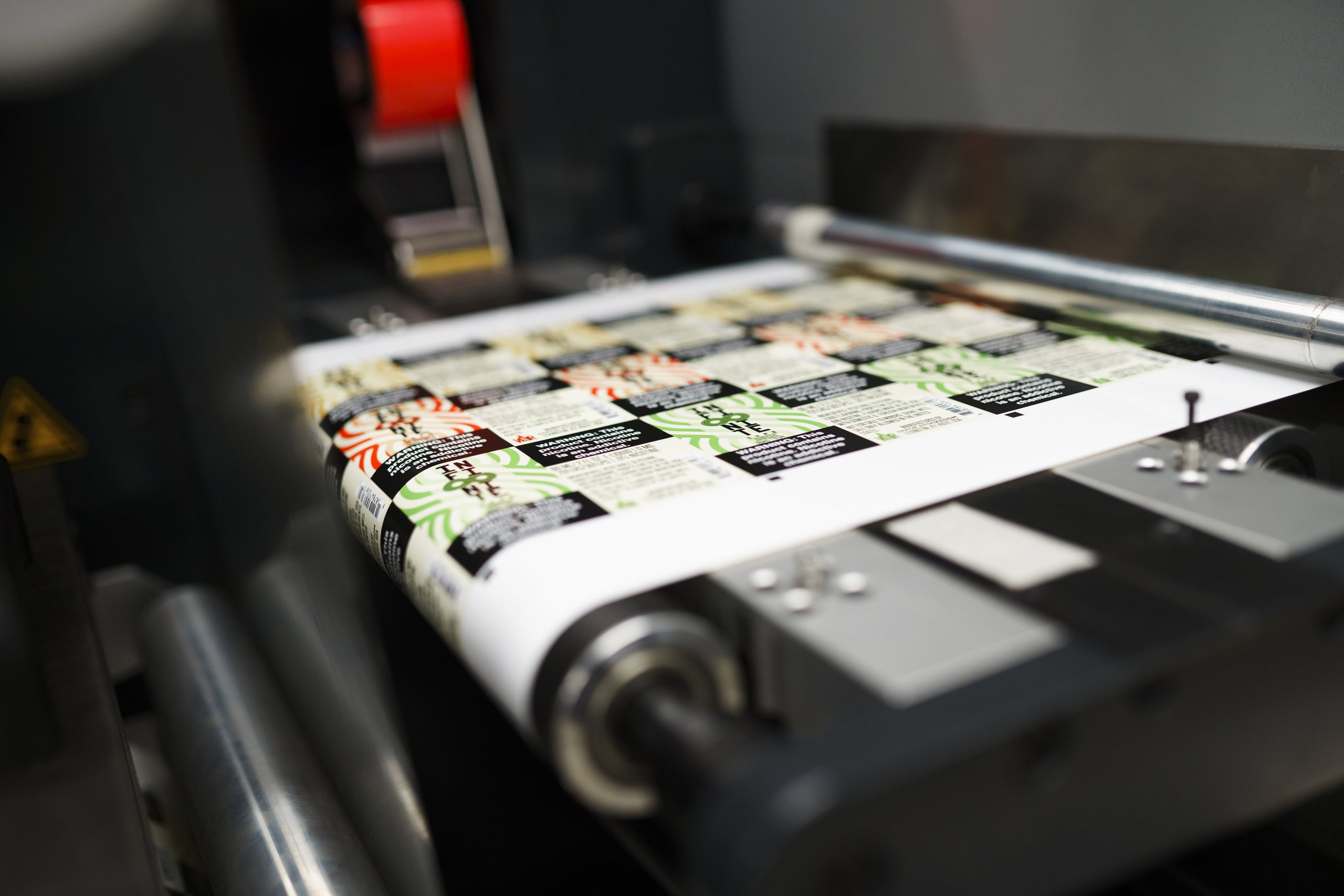

The Different Types of Label Applicators

When you’re tired of applying labels by hand, there are two main routes your company can take – handling application internally and hiring an outside vendor.

There are plenty options available if you want to handle label application internally. DIY applicators range from tabletop devices to fully-automated machines. There are also applicators made for specific types of labels and containers. For example, a shrink sleeve applicator is vastly different from a machine made for wraparound bottle labels.

As you may expect, the more automated machines are typically more expensive. Those extra costs typically translate in added efficiency, with some automated machines applying more than a thousand labels per hour. However, even tabletop devices will speed up your process compared to hand application. That investment in applicating equipment will also produce more consistent results, effectively limiting application issues like bubbling and wrinkles.

If you aren’t interested in handling the label application process internally, an outside vendor can take on that work for you. Companies like mobile canners and bottlers will come to your brewery, distillery, or other type of business and set up temporary application lines. Other professional applicators have internal systems where you can have them label your packaging in their own facility.

How to Choose Between Different Label Applicators

Both DIY and professional label application are viable options. However, each route offers certain advantages and disadvantages. A big brewery or a small specialty foods company will have different pain points that may make one option more attractive than the other. As such, it’s important to weigh what matters most for your business.

Advantages of DIY Label Applicators

Long-term financial viability.

Your budget is arguably the biggest factor when it comes to choosing the right label applicator for your business. It’s no secret that investing in labeling equipment is a notable investment, especially if you opt for automated machines. Manual machines are more affordable, but less efficient and consistent. Your financial flexibility can dictate exactly what you can get or if you’d prefer to pay as you go for professional application.

Of course, that initial investment is a big reason why in-house label application is best for long-term savings. You invest that capital up front on equipment, training, and space, but you’ll make that money back over time.

Flexibility in terms of timing.

One of the biggest benefits of investing in your own applicators is that you don’t need to rely on outside schedules. Using a mobile canning company or some other professional label applicator means that you need to work around their timelines. If you have a filler-applicator in house, you dictate when it’s time to fill your containers and apply your labels.

Advantages of Professional Label Applicators

Capital and space.

While taking a DIY label application approach can save you long-term, they do require an initial investment. Professional applicators can help businesses that either aren’t in a position to make that investment or want to keep their cashflow flexible for the near future.

Professional label applicators also help businesses that struggle with space. It’s not uncommon that businesses simply don’t have room for permanent canning or bottling lines and other sizable equipment. Mobile canners and bottlers make it so that you only need to clear space for a day before it’s returned to a normal work area.

No extra labor.

Sometimes your business doesn’t have the staff to accommodate label application in house. It takes a lot of time to make your product, clean, work the floor, handle accounting, and complete every other essential job. With professional label applicators, you don’t have to worry about training people and dedicating their and your valuable time to yet another task.

Less responsibility.

There’s a lot of value in not having to incur the cost when something goes wrong. Professional vendors are responsible for any issues or other problems that occur with their equipment. Those issues can range from fixing application issues to cleaning up messes and maintaining machinery. If you don’t own the equipment, you won’t need to spend your valuable time addressing those issues.

Make Sure Your Labels Match Your Applicator’s Requirements

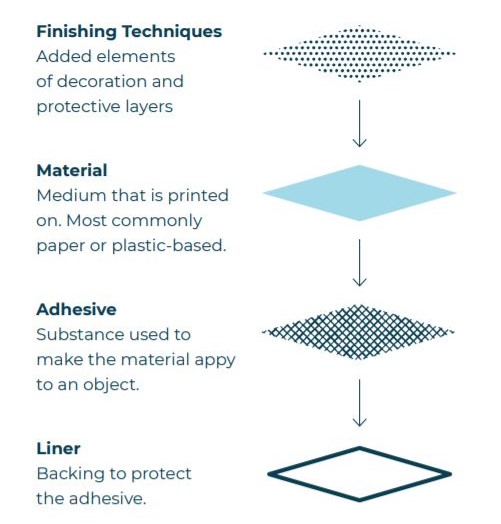

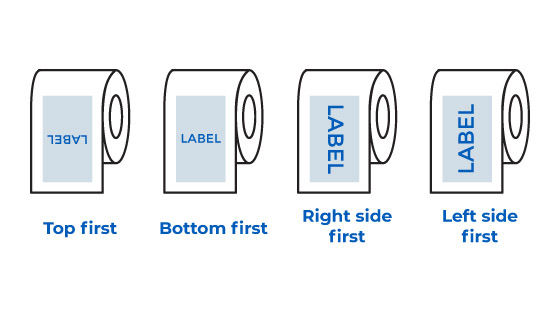

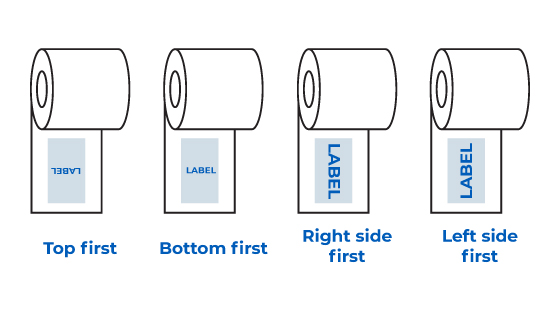

Whether your invest in DIY equipment or hire an outside company, your labels will likely need to meet certain specifications.

As such, you’ll need to ensure that your equipment of professional applicator can accommodate certain label specifications. Details like roll sizes, container shape, and unwind requirements should all align with your choice of applicator. If they don’t, your labels will end up with visible issues – and that’s if they can even be applied in the first place.

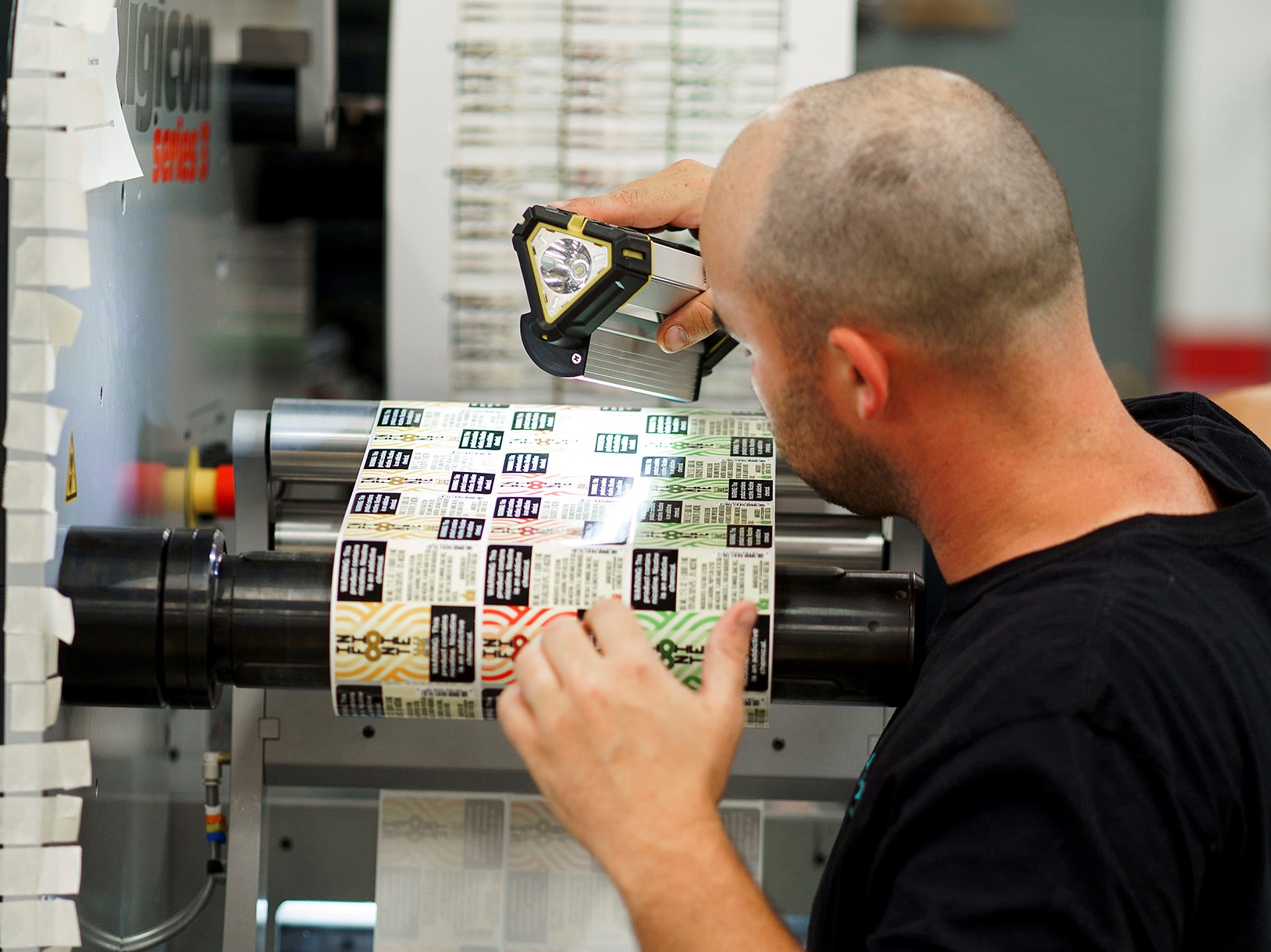

No matter your choice of applicator, a good label printing company can help you quickly match your label specifications and set you up for success. Blue Label works directly with you to identify these criteria and quickly produce durable, eye-catching labels for your products. Your labels need to tell your story. Our team can make sure your story isn’t derailed by application issues and other problems.

Ready to invest in labels tailored for your exact needs? Contact us today to talk to one of our experts about your next label project.