What is a Shrink Sleeve Label?

⚞ The Highlights:

- Shrink sleeves wrap completely around a container, giving you 360-degree coverage for eye-catching designs

- They add an extra layer of coverage, help reduce scuffs, and show tamper evidence, so people trust your product hasn’t been messed with

- Shrink sleeves conform to containers with curves or unusual shapes, letting you explore bolder branding options than traditional labels might allow

When you want to brand your product from top to bottom, shrink sleeve labels give you a way to create 360-degree coverage for your products. Shrink sleeves have grown in popularity over the past few decades after making an initial splash when Tylenol used them to combine attractive labeling with tamper-evident sealing.

Shrink sleeves are now growing in popularity for cans, bottles, and other containers, but there are still many people in need of quality product packaging who don’t know how these labels work. Here’s a quick breakdown of what a shrink sleeve label is and what makes it different from other labeling solutions.

What is a Shrink Sleeve?

Shrink sleeve labels are full-color, 360-degree printed labels that utilize heat in the application process to conform the label to the shape of the container. The labels are typically printed on either plastic or polyester film material and are commonly used on aluminum cans and glass or plastic bottles.

Looking for Custom Shrink Sleeves?

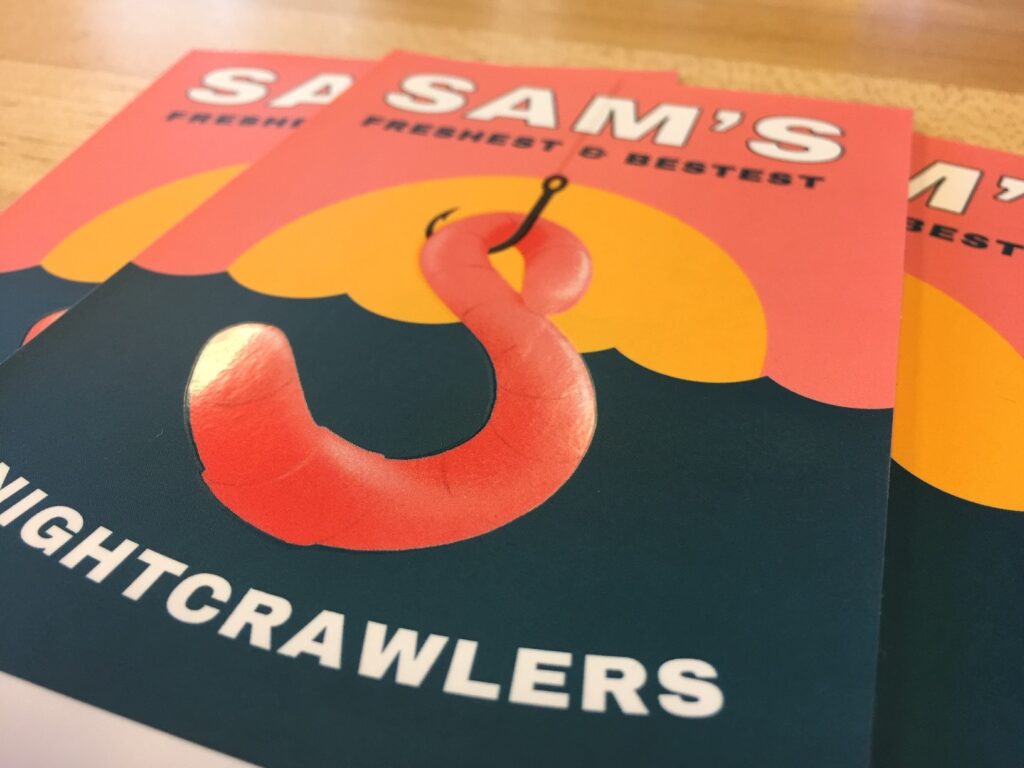

Custom shrink sleeve labels allow you to add a “second skin” to your containers. When the film sleeve is placed around your container and heat is applied, it conforms to the shape of the container to create a look like it’s truly part of your product.

Request a Quote Get a Sample Pack

Benefits of Shrink Sleeves

One of the greatest advantages of using shrink sleeves is that it allows you a 150 percent increase in label real estate compared to pressure sensitive labels. This additional space can be used to help tell your brand story, add more imagery, or make room for all of the regulatory information that needs to go on your label.

Beyond branding, shrink sleeves can function as more than just a label. Like in the Tylenol example, shrink sleeves can double as tamper-evident sealing to give your products the extra security they need with a perforated shrink cap. Shrink sleeves can also be used to package multiple items together for the purpose of offering it as one product. Because shrink sleeves are form-fitting, you can package different sized and shaped containers, like free samples or two-for-one deals, together easily.

Another benefit of using shrink sleeves is that they are very made of very durable materials. This makes them an excellent labeling option for products like hair care products and beer that are often in humid or moisture-heavy environments like showers and refrigerators.

How Do Shrink Sleeves Work?

Like regular labels, shrink sleeves give you a means to add branding and product information on a container. The process of applying a shrink sleeve involves shrinking a film sleeve with steam or heat so that it conforms to the shape of your container instead of laying on the surface with an adhesive. However, before you can apply the shrink sleeve there are a few different steps that have to happen.

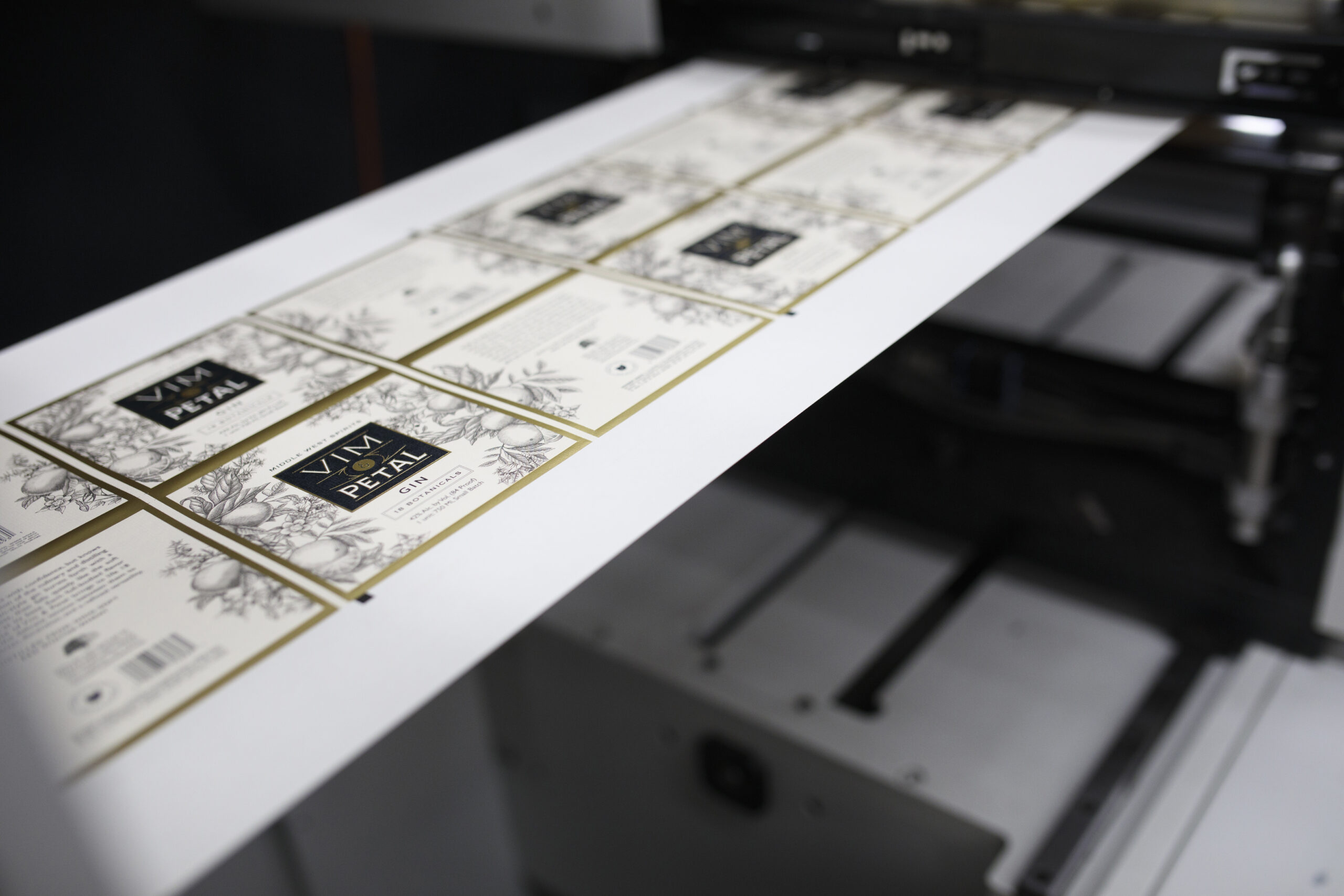

Creating the sleeve

As the name suggests, one of the key differences between shrink sleeves and pressure sensitive labels (i.e. sticker-like labels) is that they come in “sleeves.” Like pressure-sensitive labels, shrink sleeves can be printed on flexographic or digital printing presses. Unlike traditional labels, the ink is printed on the inside of the sleeve instead of on top of the label material. This allows the film to naturally protect the ink as it adheres to the container.

Once the sheets are printed, they need to be converted into sleeves. Some print shops, like Blue Label, do this step in-house to limit the number of times people handle these delicate products before they are applied. Other printers may need to send the sheets to shrink sleeve converters, which results in more opportunities for someone to mishandle the shrink sleeves, obstruct the ink, or cause some form of damage to these labels.

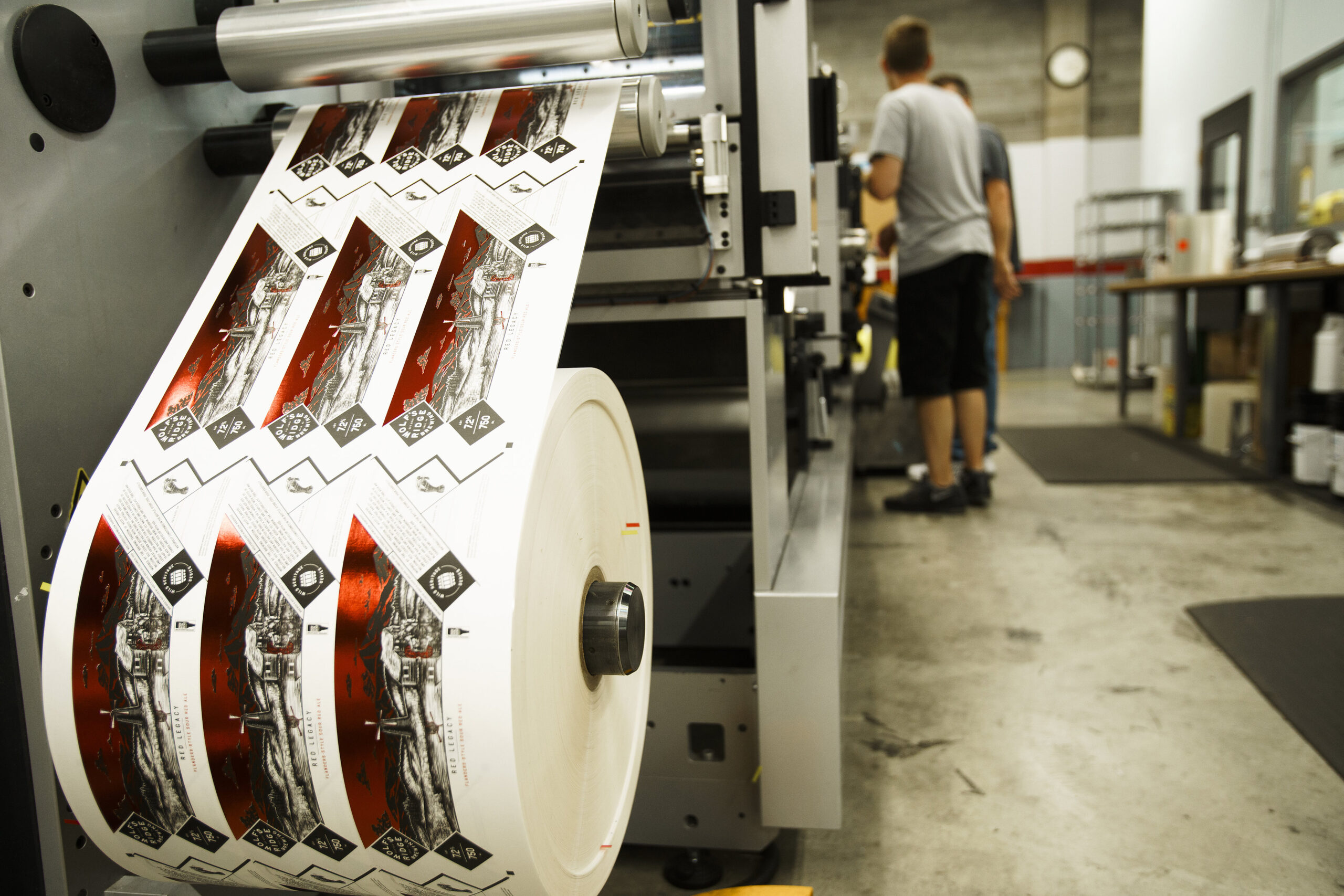

Regardless of who completes the process, the converter will seam the ends of the sheets together to leave openings at the top and bottom of the newly created sleeve. This is done by taking the ends of the film and sealing them together with a specific type of glue to create a loose cylinder. These seams are then inspected to ensure that the sleeves won’t break open as they’re applied. Once done, the film is inspected and shipped as either rolls or individual sheets depending on your application needs.

Adjusting the design to the sleeve

One of the big draws of shrink sleeves is that it conforms to the shape of your container: every angle, curve, or unique shape. However, this also means that your label design needs to be properly prepared to conform to this shape as well.

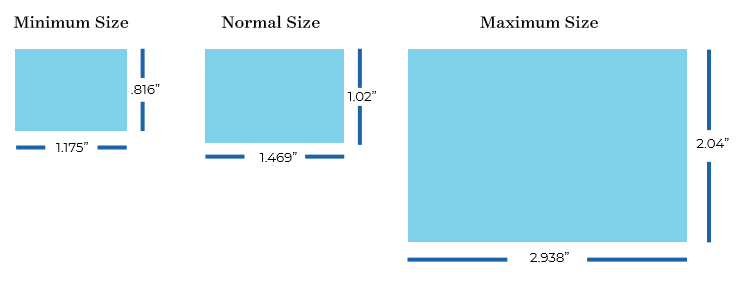

Due to the shrinking process, your label design will warp as the sleeve is heated and conforms to your container. Similar to how you need to adjust your design for tapered pressure-sensitive labels, you’ll need to pre-distort your design based on the shape of your container. As such, you’ll want to work with a label designer and label printer who can pre-distort designs for custom container shapes before your sleeves are printed.

Applying the sleeve

Once your sleeves are ready, it’s time to apply them to your containers. In addition to printers – and sometimes converters – you may also require an applicator if you don’t have the right equipment in house. Either way, the sleeves are slipped over your containers and sent through a heat or steam tunnel, where the intense heat will shrink the film around the container.

It’s important to note that since the film is made to react when exposed to heat, it’s vital that they don’t get too hot or cold before they’re applied to your containers. Excess temperature in either direction can cause pre-shrinkage or affect the ink on the labels, which can impact the quality of the label and even render them unusable. As such, proper storage and shipping is a must, especially since you may require multiple locations to create and apply shrink sleeves.

How Do I Work with a Shrink Sleeve Label Company?

Ready to cover your containers with quality shrink sleeves? First, you’ll need a good designer if you don’t have one already. Check out our designer directory to find a professional that can help you achieve the perfect look for your products.

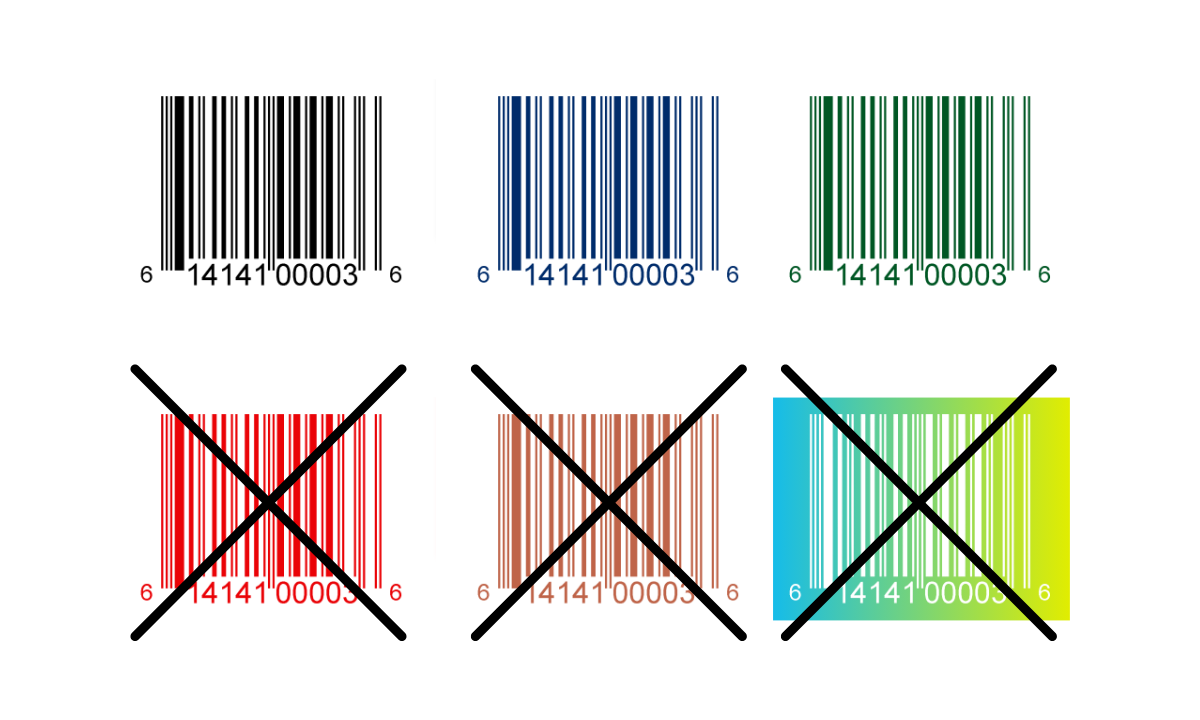

Once your design is ready, you’ll need to find the right shrink sleeve label company. At Blue Label, we have the experts and equipment to guide you through the shrink sleeve printing and converting process. Our hands-on team will work with you to identify opportunities, such as testing barcodes that may be skewed from the shrinking process. We can then carefully ship your shrink sleeves to your applicator of choice to help you get your products to market.

Contact Blue Label today to talk to one of our experts about investing in shrink sleeves for your products.