Finding the Perfect Match: Beer Container Types and Beer Labels

- Beer

- beer kegs

- beer packaging

- bottle labels

- can labels

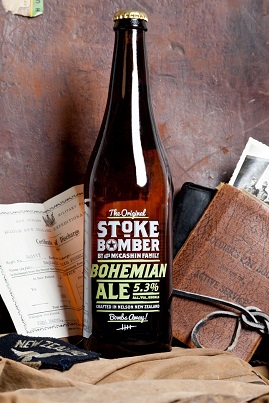

Think beer labels are only good for traditional beer bottles or cans? Think again. From growlers and bombers to different sized beer cans, beer labels make the perfect addition. Here at Blue Label Packaging Company, we have experience designing and creating bottle labels for a variety of shapes and sizes.

It’s not just the label that can set a beverage apart from others. It’s the container type, too. Take a look at some of our favorite beer storage containers below:

1. Beer Cans

Why do brewers love cans of beer so much? They’re lightweight, cost-effective, and easy to transport, plus the metal blocks out light better than glass, helping protect beer flavor. Cans are also highly recyclable, which can be an appealing sustainability factor for both brewers and consumers.

The coolest thing about types of beer cans are the size variations – you don’t have to stick with the standard 12-ounce can.

Common Can Sizes

The following are some of the most common beer can types:

- 8.4 oz (often used for specialty releases or high-ABV beers)

- 12 oz (the classic “standard” can)

- 12 oz slim (same volume, narrower profile)

- 12-ounce “Sam Can”, produced by the well-known Boston Beer Company

- 16 oz (“tallboy” or “pint” can)

- 19.2 oz (“stovepipe,” often sold as single-serve)

- 32 oz crowler (an aluminum growler used by taprooms)

Beer Can Label & Shrink Sleeve Dimensions

For 12 oz cans, you’ll typically see pressure-sensitive labels around 3.75”–4” tall by 8”–8.5” wide.

16 oz cans often use labels around 5” tall by 8”–8.5” wide.

If you’re using shrink sleeves, the label height can cover the entire can from top to bottom—often 5”–6” for a 12 oz can, or 6”–7” for a 16 oz can—depending on how much real estate you want for your design.

2. Beer Bottles

Beer bottles remain a staple in the industry—despite cans dominating much of the craft market, bottles of beer still have a loyal following.

A significant portion of craft beer sales continues to come from glass beer bottle formats, especially for specialty releases. They’re popular for their traditional look and the perception that glass can enhance a beer’s taste and presentation.

Some brewers also prefer bottles for high-gravity or barrel-aged brews, believing they allow for more nuanced aging and flavor development.

Why Choose Beer Bottles?

Brewers often opt for bottles because:

- Brand Image: Glass can evoke a premium or nostalgic feel.

- Flavor Preservation: Dark glass helps shield beer from harmful light.

- Tradition: Many craft consumers still associate bottles of beer with authenticity and craftsmanship.

Common Bottle Sizes

- 12 oz – The classic standard for many craft and mainstream beers

- 22 oz (“Beer Bomber”) – Frequently used for limited-edition or specialty brews

- 16.9 oz (500 mL) – Popular among breweries with European roots

- 750 mL – Often used for high-end or Belgian-style releases

Beer Bottle Label Dimensions

Beer bottles typically use a front label and a back label, though some breweries choose a single wrap label that goes all the way around.

A common front label might be around 3 x 3 inches, while the back can vary between 2.5 x 2.5 inches and 3 x 4 inches depending on the bottle shape and how much legal info you need.

3. Beer Growlers

Often used for transporting craft beer from breweries, amber glass growlers have an iconic jug-like shape with a convenient handle.

Why do brewers turn to growlers? They’re refillable, reusable, and give customers a chance to take home fresh beer straight from the tap.

Common Growler Sizes

Most growlers hold 64 oz or 32 oz, though gallon sizes (128 oz) are also available for those who want more volume.

Common Label Dimensions

Labels for growlers generally fall in the 4–5 inch (height) by 4–6 inch (width) range, depending on the curved surface and branding needs.

Some brewers opt for larger, wrap-around labels—like 4 x 14 inches—for maximum coverage.

4. Beer Kegs

Beer kegs have always played a huge role in draft beer consumption—particularly in bars, restaurants, and taprooms. A lot of craft beer sales happen “on-premise,” and aluminum beer kegs are the go-to container for delivering fresh drafts.

The choice to use kegs often comes down to cost-effectiveness (they’re refillable and reusable), minimized packaging waste, and straightforward shipping logistics.

Why Choose Beer Kegs?

- Bulk Distribution: Ideal for high-volume, on-premise service.

- Quality Control: Minimizes oxygen exposure, keeping beer fresh for longer.

- Sustainability: Reusable containers reduce packaging waste.

- Cost Efficiency: Fewer materials compared to individual cans or bottles.

Common Keg Sizes

- Half Barrel (1/2 bbl): 15.5 gallons—standard for bars and large events.

- Quarter Barrel (1/4 bbl): 7.75 gallons—often referred to as a “pony keg.”

- Sixth Barrel (1/6 bbl): 5.16 gallons—popular for smaller tap rotations or limited releases.

- Cornelius Keg (“Corny Keg”): 5 gallons—often used by homebrewers and smaller-scale operations.

Common Label Sizes for Kegs

Beer keg collars sit around the top of the keg and usually measure 6–7 inches in diameter, depending on the collar’s design. They’re important for compliance (listing style, ABV, and brewery info) and branding.

Some brewers also use keg wraps—long, narrow labels that can wrap around the keg’s body. These typically run 4–6 inches tall and up to 30 inches wide, though dimensions vary based on the keg’s circumference.

If you’re looking to add color and branding, a well-designed wrap can stand out in a crowded cellar or cooler.

5. Beer Barrels and Casks

Barrels and casks are commonly used by craft beer breweries for aging or secondary fermentation, typically after the initial brewing process. They can infuse unique flavors (like oak, bourbon, or wine notes) into the product, resulting in more complexity.

Brewers often choose a beer barrel when they want to create limited-edition or specialty batches that stand out in the market. It’s all about achieving deeper, layered profiles that can’t be replicated in stainless steel tanks.

Why Use Barrels or Casks?

- Flavor Enhancement: Wood barrels or casks previously used for spirits or wine can add distinct characteristics—vanilla, caramel, tannins, or even residual whiskey notes.

- Extended Aging: Slower oxygen exchange creates subtler, more nuanced flavors over time.

- Brand Differentiation: Barrel-aged beers can command premium prices and generate buzz among craft enthusiasts.

Common Barrel and Cask Sizes

- Standard Barrels (53 gallons): Often repurposed from bourbon distilleries, the most common size in the U.S.

- Wine Barrels (59 gallons): Popular for sour or wild ales, imparting vinous qualities.

- Hogsheads (66 gallons): Larger barrels sometimes used for extended aging.

- Firkins (9 gallons): A smaller, traditional British cask used for real ale or specialty releases.

- Pins (4.5 gallons): Half the size of a firkin, ideal for small-batch cask ales.

Choosing the right size depends on your goals: smaller casks let you try new recipes without a big commitment, while larger barrels hold more product for extended aging and complex flavor development.

Your type of beer container doesn’t have to be the only packaging feature that sets your beer a part. Likewise, your beer labels don’t have to be the only unique part of your beer bottles or cans. Beer containers and labels can – and should – work together to bring the product to life. Use them both to your advantage, and contact us today to find out how.