Weighing the Pros and Cons of Beer Canning

More and more craft breweries are switching to beer canning as opposed to traditional beer bottling. With more than 3,000 breweries in the U.S., it’s no wonder – there are tons of great reasons to switch to canning. With that said, there are also some negatives. We’ll help you weigh the pros and cons below.

More and more craft breweries are switching to beer canning as opposed to traditional beer bottling. With more than 3,000 breweries in the U.S., it’s no wonder – there are tons of great reasons to switch to canning. With that said, there are also some negatives. We’ll help you weigh the pros and cons below.

Pro: Beer canning is becoming easier

Have you heard of mobile canners?* This new trend is making it extremely easy for small craft breweries to can their beer. Mobile canning companies travel with their equipment from one brewery to the next, where they spend a few hours filling cans. According to the Wall Street Journal, more than two dozen companies have begun offering mobile canning services to craft breweries.

*Note: there’s one mobile canning company not too far from us here at Blue Label Packaging Company. Buckeye Mobile Canning is located in Amherst, Ohio – just west of Cleveland.

Con: Beer canning may turn away some customers

Let’s face it – there are craft beer lovers out there who think canned beer only means mass-market beer. This means they might be turned off by the simple fact that your craft beer comes in can form. As the trend continues, more and more consumers, especially those who are knowledgeable about craft beer, are used to seeing high quality beer in cans. But, there are still those traditionalists who chafe at the idea of great beer coming in a metal can.

Pro: Beer canning is better for taste

Many beer experts believe the beer in cans tastes better. Why? Because cans tend to seal tighter than bottles. They also do a better job of preventing light from striking the beer, which can give the beer a “skunky” taste. Sunlight breaks down hops molecules, which creates a chemical reaction with the sulfur in the beer. This creates the same stinky chemicals used by a skunk. Now you know.

Con: Beer canning equipment can be expensive

If you plan to can your beer yourself, you might not like that idea that canning equipment can cost as much as $200,000, if not more. You’ll also need a place to store all of the equipment, and a trailer if you plan to travel with it. Not to mention, the minimum order size for screen printed cans can belarge. More brewers are embracing labeled cans, which provides small batches of canned beer without having to screen print huge quantities. But, most commonly, it’s expensive to get the printed canned inventory you need for production.

Pro: Beer canning allows brewers to save money

Depending on who is doing your canning, switching to canned beer has the potential to save you money in the long run. You’ll mainly save in the area of shipping, because a case of cans weighs about a third less than a case of bottles. Plus you’ll be able to ship more – as many as 2,000 cans fit into a shipping container, while only 1,350 bottles usually fit.

At the end of the day, it’s up to you to weigh the pros and cons of switching to canned beer. There are advantages and disadvantages on each side. Regardless, there’s no denying that more craft breweries are switching to canned beer – and the trend is expected to continue. If you do decide to switch to cans, we’ll be here to help with your beer labels. Just give us a call.

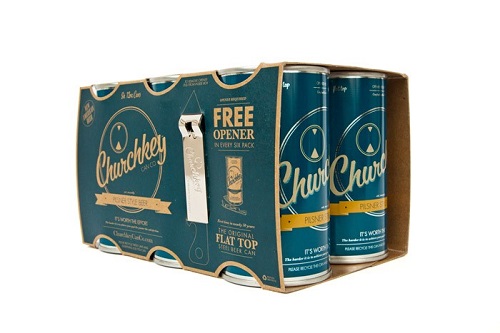

(Image source: thedieline.com)